There is plenty of guidance on inspecting masonry construction in the Masonry Standards Joint Committee (MSJC) Code and Specification and the International Building Code. Even so, looking at a job should be the jurisdiction of trained inspectors, people who have taken classes to understand what is expected for each level of testing, are familiar with the test methods, and who have passed a certification test. This ensures that they know enough about masonry construction to perform inspections effectively and efficiently.

Masonry construction is a proven method but building design and philosophy are constantly changing. One of the significant changes affecting new masonry in recent years is that design loads (or the period over which the loads may act) have been modified. So in a given region, even though an earthquake is no more likely today than it was during the past, designers have to consider higher magnitude (earthquake) forces when designing masonry. This means that buildings must be designed more robustly even though the likelihood of an earthquake occurring has not changed.

In many parts of the United States, areas now may be considered to be at a higher level of risk. Even those areas that have traditionally been at low risk of seismic activity may require buildings be analyzed for (or built to resist) some earthquake forces. As a result, where masonry walls once had little or no reinforcement, they more often have increased quantities of steel and are partially or fully grouted.

As part of this increased focus on reinforced masonry, quality assurance (QA) programs become more important. Inspection is one of the key activities in quality assurance programs, so it logically follows that inspection is more important now than previously. Special inspectors are the people who have the training and knowledge to look at masonry walls as they are constructed to assure that they are being built according to plan. Inspectors are trained to look for unobstructed grout spaces, how to check the placement of reinforcement, and how to test mortar and grout. They watch over construction as it proceeds to see that contractors are doing the right things.

Trained, qualified inspectors are needed to implement effective inspection programs. Two aspects of meeting that need are training and certification of masonry inspectors. Providers of training programs for masonry inspectors include various local and regional masonry institutes, and national or international organizations such as The Masonry Society (TMS). The International Codes Council (ICC), publisher of the International Building Code (IBC), also provides a Structural Masonry Special Inspectors Certification Exam, which is co-sponsored by TMS. For additional information on availability of masonry inspection training programs and the Structural Masonry Special Inspectors Certification Exam, contact TMS or ICC.

Masonry Construction Special Inspections

All types of construction are inspected. Inspection is a way of ensuring that builders are doing what the designer intended, and ultimately, that the owner is getting what they want. As masonry construction continues to evolve, it’s increasingly important to know how to inspect the work. There is guidance in various building codes and specifications to help us know what to inspect for each type of building and how often to inspect it.

What are some of the reasons we need to inspect construction? For one thing, contemporary masonry construction can be more highly detailed than in the past. For another, this is a way of catching mistakes while they are still relatively easy to correct. Having someone check the builder’s work is a reasonable and necessary safeguard.

In many parts of the country, building codes define requirements for inspection to ensure that masonry structures provide for public lifesafety. “Special inspection” is the designation given to this activity, with specific requirements for activities and frequency of them to ensure quality in construction.

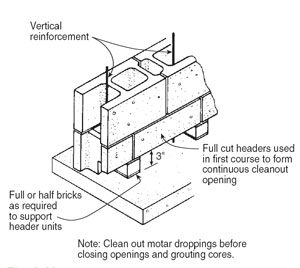

Grout cleanouts, which the contractor uses to prepare the space for grouting, allow inspectors to verify that reinforcement has been properly placed and tied.

Inspection is only one aspect of a quality assurance (QA) program, which is the overall plan for verifying construction. QA programs are how compliance with contract documents is verified. Public safety is addressed by instituting minimum code requirements, which may be modified by the local building authority. In the United States, the International Building Code (IBC) and the Masonry Standards Joint Committee (MSJC) Building Code Requirements and Specification for Masonry Structures are typically referenced for inspection requirements. Both documents define different levels of inspection for masonry construction on the basis of facility importance and design procedure. However, the IBC designates two levels of special inspection (Level 1 and Level 2) while the MSJC Code and Specification designates three levels of quality assurance provisions (Level A, Level B, and Level C), which include inspection requirements. IBC Level 1 special inspection requirements generally parallel MSJC Level B criteria and IBC Level 2 parallels MSJC Level C, although there are some differences, primarily in requirements for frequency of inspection.

MSJC addresses inspection in the Code in Section 1.15 under the heading "Quality Assurance Program" and in the Specification in Section 1.6 under the heading "Quality Assurance." The IBC addresses inspection requirements in Section 1704.5.

Within the MSJC Code and Specification, Level A is the basic, or least stringent level and Level C is the most rigorous. From one level to the next, requirements are progressive, so whatever you do for Level A, you have to do that and more for Level B, and you have to address all of these requirements for Level C. Where you can use each level is outlined in the following table, although an owner or designer always has the option of increasing the inspection requirements.

| Quality Assurance Level | Where to Use | Construction |

| A | Nonessential facilities* | Empirically designed masonry

Glass unit masonry

Masonry veneer |

| B | Nonessential facilities* | Engineered masonry |

| B | Essential facilities* | Empirically designed masonry

Glass unit masonry

Masonry veneer |

| C | Essential facilities* | Engineered masonry |

| *As defined by building code, a facility’s importance and the design procedures employed define the appropriate level of inspection. A hospital is one example of an essential facility. Qualified inspectors should observe construction to verify compliance with material specifications and that the as-built project conforms to the contract documents and building code.

References Building Code Requirements for Masonry Structures and Specification for Masonry Structures and Commentaries, Masonry Standards Joint Committee, American Concrete Institute, American Society of Civil Engineers, The Masonry Society, Boulder, Colorado, 2005. |