Useful Service Life FAQs (Click for more)

Fire Resistance FAQs (Click for more)

Stucco and Moisture Resistance

Stucco over concrete masonry is popular, in part, because it is very durable in high humidity environments. Although most prevalent in Florida, stucco is estimated to be used on as much as 20 percent of block installed in the United States. Where this kind of finish is also subject to high winds, concern has been raised about how well it resists wind-driven rain.

Phase I test walls show wall panels with water chamber assemblies mounted on them.

The following article summarizes new research about traditional stucco over concrete masonry to determine the system’s effectiveness in resisting moisture penetration. Testing was done in a laboratory, using test periods of 28 hours and high winds (up to 180 miles per hour) as might be expected during hurricanes.

Following the 2004 hurricanes that hit Central Florida, significant moisture penetration and damage was noted on new block homes, residences constructed after 2001. To help determine what happened, the Florida Concrete & Products Association (FC&PA) contacted the National Concrete Masonry Association (NCMA) and set up a research project under the direction of Jim Gulde, a noted stucco expert.

Objectives of the Two-Phase Study

The objectives of the project were as follows:

- Generate data on water intrusion through stucco over concrete masonry

- Evaluate performance based on stucco thickness and masonry workmanship

- If the water penetration performance was favorable, provide information to assist marketing efforts for concrete masonry

Stucco was installed in accordance with industry practices, although thinner applications (1/8- and ¼-inch) than allowed by code were made for comparison with code-and standard-recommended thicknesses. Some joints between units were also purposely left unfilled to evaluate the effect of workmanship. (See table.)

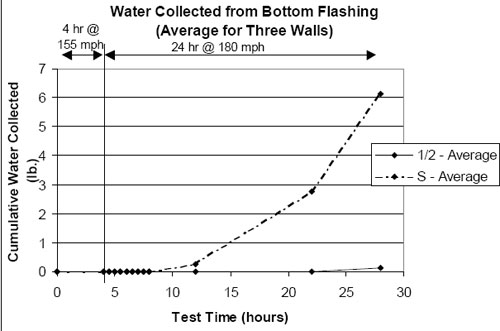

The study was completed in two phases, the first at lower wind speeds and the second at higher speeds as shown in the table. Using 4-by-6-foot panels subjected to the ASTM E 514 protocol (Standard Test Method for Water Penetration and Leakage through Masonry), the moisture penetration through the walls was observed and recorded as:

- area of wall surface affected and

- amount of water collected on through-wall flashing.

Findings and Conclusions

Portland cement plaster over concrete masonry is an effective finish for resisting water penetration into and through the walls. It should be installed in accordance with industry practices—the proper mix at the correct thickness, followed by curing—to achieve its full potential. A complete description of industry practices is available in ASTM C 926, Standard Specification for Application of Portland Cement-Based Plaster.

- At wind speeds of 110 miles per hour (mph), all the coated walls resisted water penetration, but the uncoated wall failed early in the testing at lower wind speeds (62 mph).

- At wind speeds exceeding 155 mph, traditional ½ inch stucco provided excellent resistance to moisture penetration.

At 180 mph, the amount of dampness on the leeward (non-wind) side of the wall was similar for both stucco material thicknesses (½- and ¼-inch). The thicker coating allowed much less water penetration—measured by water collected on the bottom of the cells on the flashing—than the skim coat (1/8 inch) at extended time and pressure.

The ½-inch coating allowed much less water than the skim coat to pass through the wall over the test duration.

Reference

The complete report, Water Penetration Testing of Stucco on Concrete Masonry Construction, was issued and is available free of charge from NCMA.

This work was completed in May 2007, a joint program of the Florida Concrete & Products Association and the National Concrete Masonry Association Education and Research Foundation. All tests were conducted at the National Concrete Masonry Association Laboratory in Herndon, Virginia.