Types of Cement

Introduction

Portland or blended cements are the key ingredient in concrete for most general construction. All portland and blended cements are hydraulic cements based on hydraulic calcium silicate. “Hydraulic cement” is merely a broader term indicating that the material forms solid hydrates following reaction with water, and can do so under water. Other special cements are used for specific applications and may be hydraulic materials or activated through other chemical methods.

Portland cements are manufactured to meet the requirements of ASTM C150, Standard Specification for Portland Cement (AASHTO M 85). The requirements of AASHTO M 85 and ASTM C150 are harmonized, and the four basic types of portland cement are Type I, Type II, Type III, Type V. Some portland cements are also labeled with more than one type designation, for example Type I/II. This simply means that such a cement meets the requirements of both Type I and Type II cement. In recent years, ASTM C150 (AASHTO M 85) Type I/II portland cement has been the most widely available in the United States.

Blended cements are manufactured to meet the requirements of ASTM C595, Standard Specification for Blended Hydraulic Cements (AASHTO M 240). Blended hydraulic cements are produced by intimately and uniformly intergrinding or blending two or more types of fine materials. The primary materials are portland cement, limestone, slag cement, coal ash, silica fume, calcined clay, other pozzolans, and combinations of these materials.

Learn more about Blended Cements

Table – Applications for Hydraulic Cements Used in Concrete Construction*

| Cement specification | General purpose | Moderate heat of hydration | High early strength | Low heat of hydration | Moderate sulfate resistance | High sulfate resistance | Air-entraining |

| ASTM C150 portland cements | I | III | II | V | IA, IIA, IIIA | ||

| ASTM C595 blended hydraulic cements | IL, IP, IS(<70), IT(S<70) | IL(HE), IP(HE), IS(<70)(HE), IT(S<70)(HE) | IL(MS), IP(MS), IS(<70)(MS), IT(S<70)(MS) | IL(HS), IP(HS), IS(<70)(HS), IT(S<70)(HS) | (A)† | ||

| ASTM C1157 hydraulic cements | GU | MH | HE | LH | MS | HS | Option A† |

*Check the local availability of specific cement types as some cements are not available everywhere.

† Any cement in the columns to the left can be used to make air-entraining cement.

General Purpose

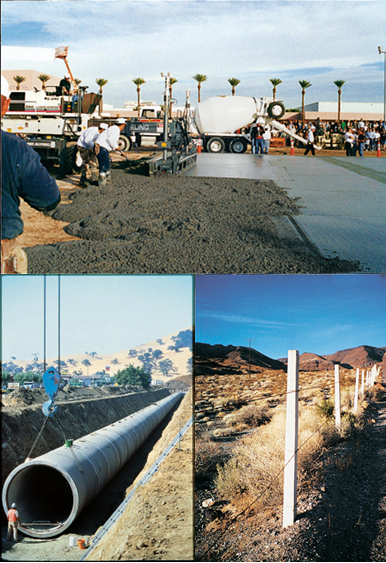

General-purpose cements are suitable for all uses where the special properties of other cement types are not required. Their uses in concrete include pavements, floors, reinforced concrete buildings, bridges, tanks, reservoirs, pipe, masonry units, and precast concrete products. General purpose cements and also used in applications such as roller-compacted concrete (RCC), soil-cement, and other geotechnical applications.

Moderate/Low Heat of Hydration

Moderate heat and low heat of hydration cements can be used where the rate and amount of heat generated from hydration must be minimized. They develop strength at a slower rate than other cement types. The broader use of moderate heat and low heat of hydration cements in the mid-1900’s has since generally been replaced with other strategies to control heat of hydration using partial replacement of cement with SCMs such as fly ash (see Chapter 5). Supplementary cementitious materials to reduce heat of hydration may be added at the concrete plant, or may be an integral component of a blended cement. .

High Early Strength

High early strength cement provides strength at an earlier age than other cement types. For example, design strength may be achieved in a matter of days as compared to the typical requirements of 28 days. It is used to achieve high-early strengths for early form removal and where a structure must be put into service quickly. In cold weather its use permits a reduction in the length of the curing period.

Moderate/High Sulfate Resistance

Moderate and high sulfate resistant cement is used where protection against external sulfate attack is necessary. Moderate sulfate resistant cement is used in structures or elements exposed to soil or ground waters where sulfate concentrations are higher than normal, but not unusually severe. Highly sulfate resistant cement is used in concrete exposed to severe sulfate environments – principally where soils or groundwaters have a high sulfate content. It tends to gain strength more slowly than Type I cement. Even high sulfate resistant cement concrete cannot withstand a severe sulfate exposure if the concrete has a high water-cementitious materials ratio. Portland and portland blended cements are not resistant to acids and other highly corrosive substances.

Sulfates in soil or water may enter the concrete and react with hydrated C3A phases, resulting in expansion, scaling, and cracking of concrete. Some sulfate compounds, such as magnesium sulfate, directly attack calcium silicate hydrate.

Concrete exposed to seawater is often made with moderate sulfate resistant cement. Seawater contains significant amounts of sulfates and chlorides. Although sulfates in seawater are capable of attacking concrete, the presence of chlorides in seawater inhibits the expansive reaction characteristic of sulfate attack. Thus, a marine environment is an application requiring a moderate sulfate exposure class. Observations from a number of sources show that the performance of concretes in seawater with portland cements having C3A contents as high as 10% have demonstrated satisfactory durability, provided the permeability of the concrete is low and the reinforcing steel has adequate cover.

Air-Entraining

An intentionally entrained air void system is a well-known and widely used strategy to improve the durability of concrete exposed to freeze-thaw cycles. Air-entraining hydraulic cements that are mixed with proper intensity and for an appropriate duration can produce concrete that contains fine, well-distributed, and completely separated air bubbles. Air entrainment for most concretes is achieved through the use of an air-entraining admixture added when batching concrete, rather than through the use of air-entraining cements. Therefore, it is advisable to check on local availability of air-entraining portland cements before specifying them.

Specifications for three types of air-entraining portland cement (Types IA, IIA, and IIIA) are given in ASTM C150 (AASHTO M 85). They correspond in composition to ASTM C150 Types I, II, and III, respectively, except that small quantities of air-entraining additions are interground with the clinker during manufacture.

Air entrainment properties may be specified for blended cement Types IL, IP, IS(<70), and IT(S<70), and are indicated appending the suffix “A” to the nomenclature. For example, an air-entraining portland blast-furnace slag cement with 40% slag that has high sulfate resistance would be designated as Type IS(40)(HS)(A). Requirements for these special properties are identified in ASTM C595 (AASHTO M 240).

Requirements for air-entraining cements are also defined in ASTM C1157 and are indicated with an “A” appended to the cement type. For example, Type GU-A is a general use hydraulic cement that has air entrainment properties.