2025 Energy & Environment Award Winners

Environmental Performance

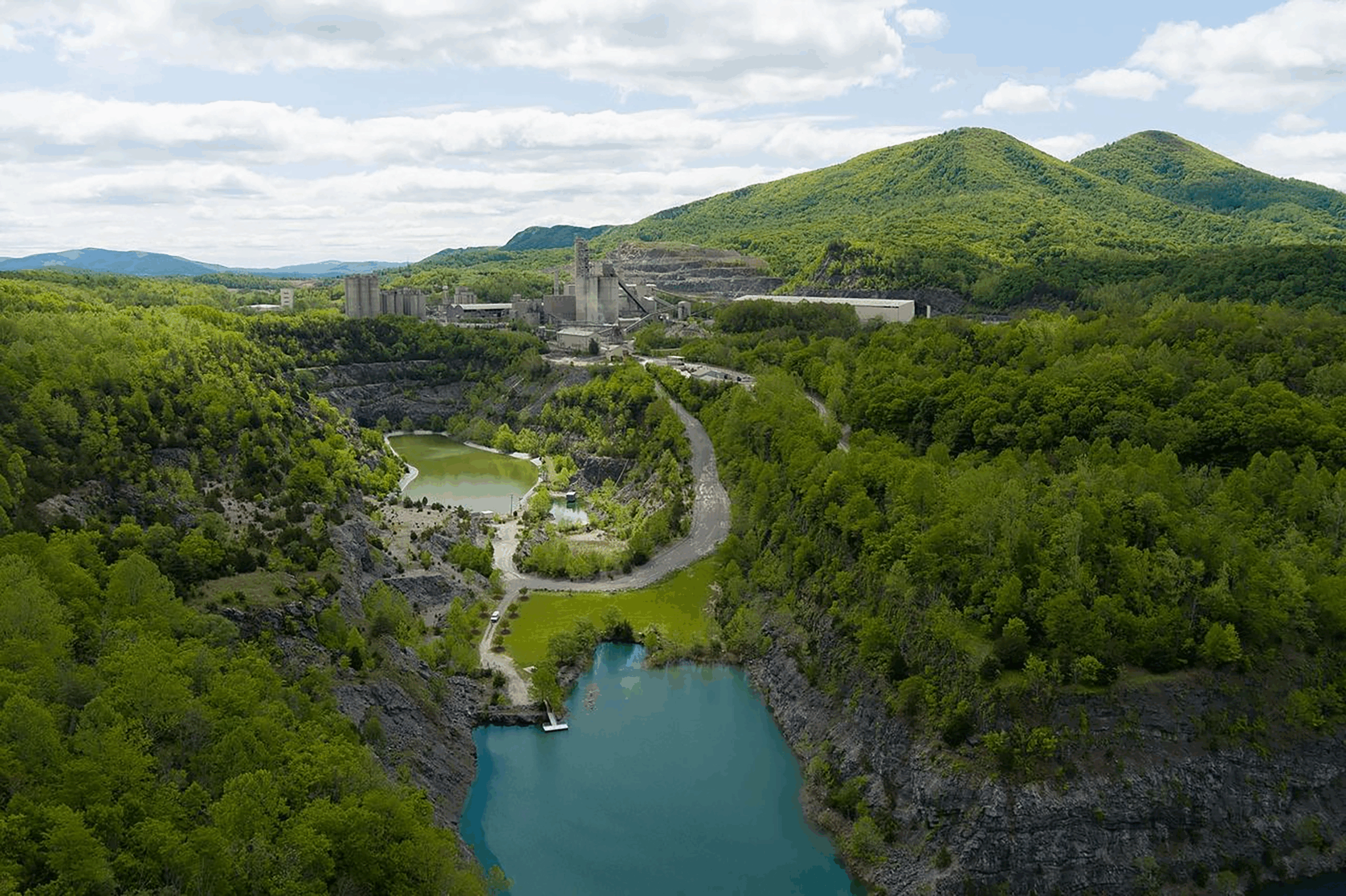

Titan America

Roanoke Cement Company – Troutville, VA

Titan America’s Roanoke Cement Company (RCC) plant has made significant progress on many fronts that earned this year’s Environmental Performance Award.

RCC scored its 18th consecutive EPA ENERGY STAR certification last year and performed energy management to the ISO 50001 standard — one of only two U.S. cement plants to do so. It has also reduced CO₂ emissions by 18% since 2020; in 2024, the plant recorded a 7.5% reduction in gross kilograms of CO₂ per metric ton of cementitious product.

Additionally, alternative fuel use contributed to a TRUE Zero Waste Gold-level recognition and an electrical energy savings of 12%. RCC was recognized this spring with National Ready Mixed Concrete Association awards for its production of lower-carbon, blended cements like Type IL, which were used in high-profile paving projects last year.

Innovative Technologies

Titan America

Titan Florida/Pennsuco – Medley, FL

Titan America’s Pennsuco plant in Florida captured this year’s Innovation Technologies or Process Award for using highly creative methods to gather data and optimize artificial intelligence solutions to raise environmental protections through predictability. New advanced condition sensors are mining hard-to-access data and driving continuous progress in operations and energy efficiency.

Pennsuco installed 18 highly sensitive sensors to monitor critical but “low rotating speed” equipment (below 10 Hz or 600 rpm). The special high-frequency sensors now pull the hard-to-ascertain vibrational measurements, bolstering its analysis. Maintenance departments can set alert thresholds with the new data that will be used to sniff out formerly unexpected failures.

A collaborative demonstration with Boston Dynamic’s robot innovation – “Spot” (or to Pennsuco workers, “Manolis”), an ever-alert, dogged inspector, finds heat, air and gas leaks through visual and acoustical measurement readings, thermal scanning, and then can calculate future vibration readings.

Better data quickly builds scale in the AI systems and subtle correlations and changes from baseline are used to help isolate problems at early, preventable stages. Savings on unexpected shutdowns reduce thermal and electrical energy use with significant environmental benefits.

Outreach

Cemex USA

Lyons Plant – Longmont, CO

In 2024, Cemex Lyons strengthened the resilience of the local natural and built environment by providing high-quality building materials to local projects as well as joining local organizations with a shared mission to build stronger communities.

By supporting and collaborating with 23 local organizations last year, Cemex Lyons helped serve the needs of thousands of residents and improved public parks, forests, trails, and other local ecosystems, including restoring areas impacted by erosion or wildfires. These efforts to enhance the community’s natural and built environments align with Cemex’s Future in Action initiative – a corporate program focused on developing lower-carbon products, solutions and processes to become a net-zero CO₂ company.

In 2024, Cemex Lyons employees volunteered more than 300 hours to support community projects, and Cemex donated more than $130,000 to further the missions of local organizations. The plant also donated more than 20,000 trees – with nearly three-quarters of those harvested from its own property.

Ash Grove, a CRH Company

Durkee Plant – Durkee, OR

In July 2024, Ash Grove Cement’s Durkee Plant found itself directly in the path of Oregon’s largest recorded wildfire—a lightning-sparked disaster that consumed more than 294,000 acres across Baker County. Located just 5 miles from the origin point, the plant’s pre-established fire lines were the only containment lines holding steady. Recognizing the critical success of those lines, Oregon Wildfire Incident Command requested support from the facility, and the Durkee team mobilized immediately.

The plant deployed its D10 and D12 bulldozers, along with skilled operators, to assist firefighters beyond the facility. More than 40 miles of additional fire lines were constructed, playing a critical role in preventing the fire’s northern spread toward nearby towns. The team’s efficiency and dedication earned them the nickname “Big Iron” from Incident Command.

The team also coordinated firefighting logistics, water access, evacuation support, and staff safety by working with the Baker County Sheriff’s Office, local ranchers, and volunteer teams to support livestock relocation, manage travel access, and ensure continuity for employees.

When the fire was finally contained on August 7, Ash Grove announced a $67,500 donation to aid community recovery efforts.

Overall Environmental Excellence

UNACEM North America

Drake Cement – Paulden, AZ

In 2024, Drake Cement LLC demonstrated exceptional environmental leadership by commissioning Arizona’s first full-scale biomass-calciner integration, replacing traditional coal-coke fuels with locally sourced forest biomass. Each ton of biomass displaces coal-coke and avoids approximately 176 kg of CO₂ emissions. This innovation reflects Drake’s voluntary commitment to achieving carbon neutrality by 2050, exceeding regulatory requirements.

Drake also earned its fifth consecutive ENERGY STAR plant certification, reinforcing its leadership in sustainable manufacturing. Across operations, Drake focused on pollution prevention, waste minimization, and supporting local ecosystems through responsible sourcing and fire management partnerships.

Additionally, Drake deepened its community engagement by conducting outreach through plant tours and participation in local job fairs, helping to educate future generations and connect with potential workforce members. Plant workers also promoted seasonal giving initiatives and food drives, underscoring their commitment to social responsibility and community support.

Energy Efficiency

CalPortland Company

Oro Grande Cement Plant – Oro Grande, CA

The CalPortland Company’s Oro Grande cement plant advanced several impressive initiatives to win ACA’s Energy Efficiency Award this year.

Staff participated in a Strategic Energy Management (SEM) program, which supplies support, guidance, coaching, and the use of an online portal to track energy performance as well as energy efficiency projects from creation to completion.

One such project involved the plant’s clinker cooler, which utilizes a heat exchanger to cool exhaust gases. The process was electricity-intensive, so plant workers developed a new system that reduced electricity consumption by nearly 2 million kWh annually.

Workers also obtained a kiln fuel consumption permit to use alternative fuels at the plant, which led to the design and installation of an alternative fuels receiving and conveying system that has a designed capacity of 6.22 tons per hour in fuel, which will displace high carbon fossil fuels and reduce the electrical load of the coal processing system.

Land Stewardship

GCC

Pueblo Plant – Pueblo, CO

GCC has earned this year’s ACA Land Stewardship Award for completing a forward-thinking reclamation project that transformed a former tire monofill in Fountain, Colorado, into a stable and naturalized landscape. Once home to more than 67,000 tons of waste tires, the site has been fully restored—well ahead of Colorado’s 2034 target for monofill closures—and now supports native vegetation and resilient ecological function.

By integrating innovative land restoration with resource recovery, GCC’s team not only rehabilitated the 46-acre site but also repurposed thousands of tons of tire material into Tire-Derived Fuel (TDF) for the GCC Pueblo Cement Plant—reducing waste and carbon emissions in the process. Careful recontouring, sustainable earthwork, and native seeding created a self-sustaining environment designed to manage stormwater naturally, minimize erosion, and promote biodiversity.

Through proactive environmental stewardship, circular resource use, and a voluntary commitment that went beyond regulatory requirements, this project demonstrates how industrial sites can be revitalized into thriving, ecologically integrated landscapes that benefit both the environment and surrounding communities.