Cement and Concrete

Cement is the key ingredient in concrete that, when mixed with water, acts as the glue that binds the coarse and fine aggregate together to create concrete. The reaction with water is what makes cement an hydraulic material and gives concrete the essential versatility to be placed in a plastic (flowable) state and then harden into a strong, durable rock-like mass. This versatility and the long-term durability are why concrete has been the material of choice for over a century to build the world’s infrastructure.

Many of the applications discussed below can be studied in greater detail in the ACA Design and Control of Concrete Mixtures. The text is backed by over 100 years of research by the Portland Cement Association (now the American Cement Association) and other industry groups. It reflects the latest guidance on standards, specifications, and test methods of ASTM International (ASTM), the American Association of State Highway and Transportation Officials (AASHTO), and the American Concrete Institute (ACI).

The Essential Ingredient

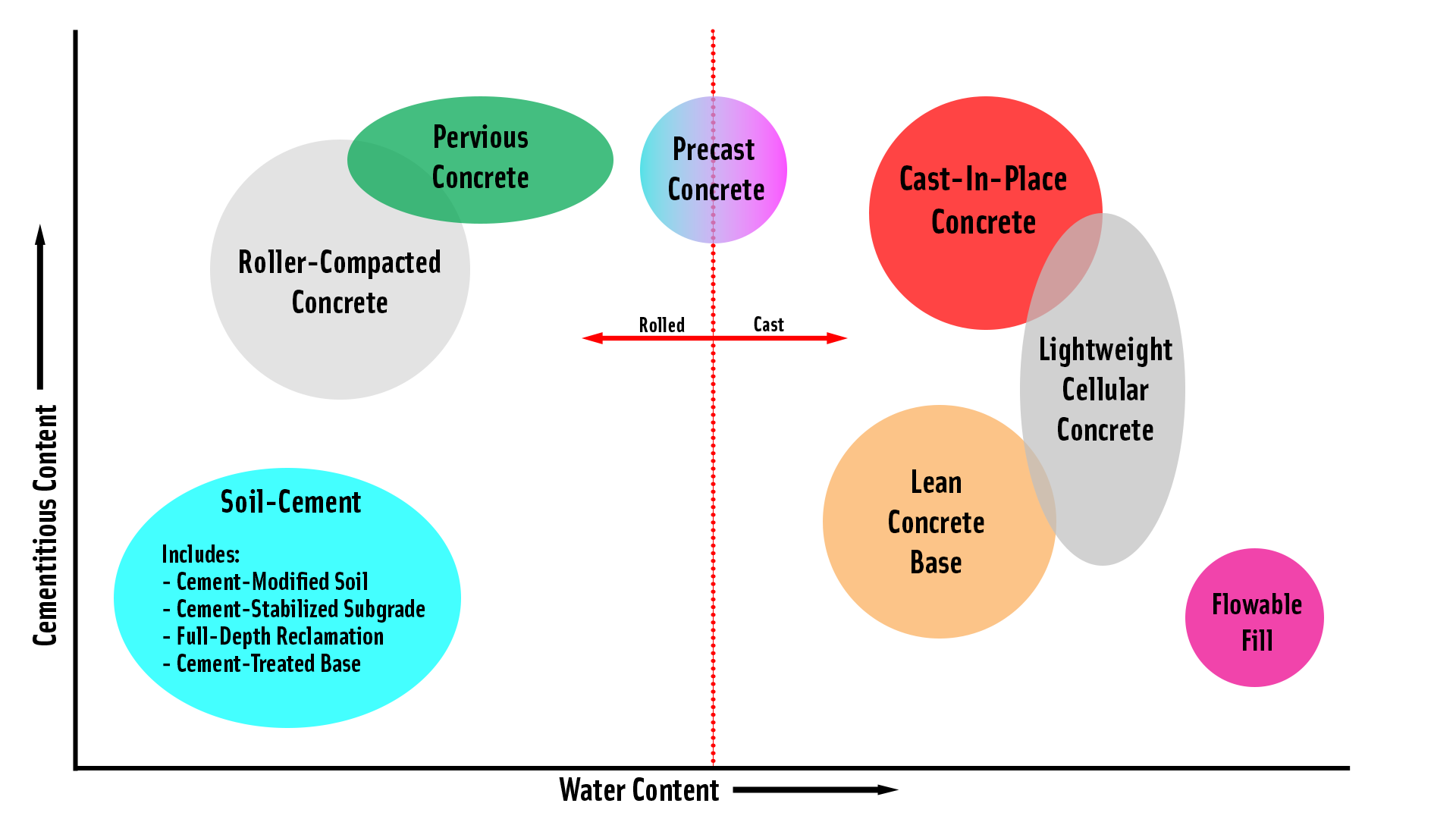

Cement is the key ingredient in concrete and the vast majority of cement manufactured in the United States is consumed for ready mixed concrete applications. Cement is the essential ingredient in many other applications, too. The proportions of cement, water and aggregate are varied and in some cases admixtures are used to achieve a wide range of fresh and hardened properties to provide solutions for essential every type of infrastructure application. The figure below shows the general relationship between cementitious content and water content for several Applications of Cement. Scroll down to learn more about the different Types of Concrete, Types of Soil-Cement, and Other Common Cement Applications.

Types of Concrete

Ready Mixed Concrete

Ready mixed refers to concrete that is batched for delivery from a central plant instead of being mixed on the jobsite. Each batch of ready mixed concrete is tailor-made according to the contractor’s specifics and delivered to the site in a plastic condition. A mixture of aggregates, portland or blended cement, water, and sometimes SCMs, fibers, and/or chemical admixtures, freshly mixed concrete is plastic enough to be placed and consolidated within formwork, where it hardens and gains strength.

Whether reinforced or unreinforced, ready mixed concrete (also known as cast-in-place or conventional concrete) is the most widely used building material in the world and accounts for nearly 75% of all concrete used annually in the U.S.

Ready Mixed Concrete Applications: Ready mixed concrete is used in a wide variety of construction projects, from skyscrapers and sidewalks to bridges, superhighways, and dams.

-

- It’s ideal for large jobs where space is limited and there is little room for a mixing plant and aggregate stockpiles.

-

There are three principal categories of ready mixed concrete.

Transit-Mixed Concrete

In transit-mixed (also known as truck mixed) concrete, materials are batched at a central plant and completely mixed in the truck and agitated during transit. Adjustments can be made to the concrete mix at the jobsite as permitted by project specifications.

Shrink-Mixed Concrete

Shrink-mixed concrete is mixed partially in a stationary mixer and mixing is completed in a truck mixer.

Central-Mixed Concrete

Central-mixed concrete is completely mixed in a stationary mixer at the concrete plant and delivered to the jobsite in either a truck mixer, an agitating truck, or a non-agitating truck. Central-mixed concrete delivered by non-agitating trucks is limited to shorter transport distances than if delivered by agitating trucks or truck mixers.

-

The key to achieving a strong, durable concrete lies in the careful proportioning and mixing of the ingredients. The quality of the paste determines the character of the concrete. The strength of the paste, in turn, depends on the ratio of water to cement. A mixture that has too little paste to fill all the voids between the aggregates is difficult to place and produces rough surfaces and porous concrete. A mixture with too much cement paste is easy to place and produces a smooth surface—but the resulting concrete is not cost-effective and can more easily crack.

A properly designed concrete mixture is workable when fresh, and durable and strong when hardened. You can produce high-quality concrete by lowering the water-cement ratio as much as possible without sacrificing the workability of fresh concrete, allowing it to be properly placed, consolidated, and cured.

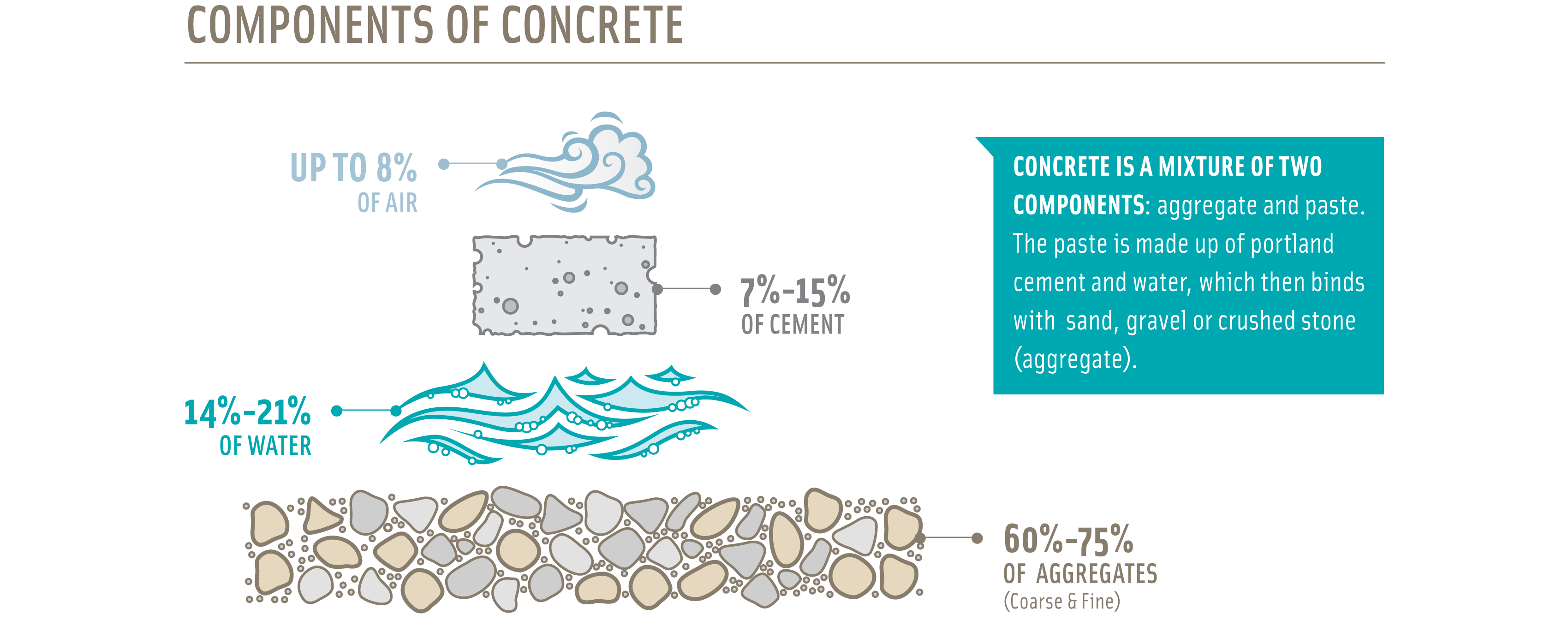

The water-cement ratio is the weight of the mixing water divided by the weight of the cement. Typically, a mix is about 7% to 15% cement, 60% to 75% aggregate, and 14% to 21% water. Entrained air in many concrete mixes may also be up to an additional 8%.

-

Water

You can use almost any natural water that is drinkable and has no pronounced taste or odor as mixing water for concrete. Excessive impurities in mixing water can affect setting time and concrete strength, and can also cause efflorescence, staining, corrosion of reinforcement, volume instability, and reduced durability. Concrete mixture specifications usually set limits on chlorides, sulfates, alkalis, and solids in mixing water unless tests can be performed to determine the effect the impurity has on the final concrete.

Aggregates

Aggregates comprise 60% to 75% of the total volume of concrete and require careful selection. The type and size of aggregate used depends on the thickness and purpose of the final concrete product.

Relatively thin building sections call for small coarse aggregate, though aggregates up to six inches in diameter have been used in large dams. A continuous gradation of particle sizes is best for efficient use of the paste. In addition, aggregates should be clean and free from any matter that might affect the quality of the concrete.

Hydration

All portland and blended cements are hydraulic cements that set and harden through a chemical reaction with water called hydration. The reaction begins soon after the aggregates, water, and cement are combined. A node forms on the surface of each cement particle. Each node grows and expands until it links up with nodes from other cement particles or adheres to adjacent aggregates.

Hydration continues during the curing process: The longer it is kept moist, the stronger and more durable concrete will become. The rate of hardening depends on the composition and fineness of the cement, the mix proportions, and the moisture and temperature conditions. Most of the hydration and strength gain take place within the first month of concrete’s life cycle, but hydration continues at a slower rate for many years.

Placement

Once the concrete is thoroughly mixed and workable but before it becomes too stiff, it should be placed in forms. During placement, consolidate the concrete to compact it within the forms and eliminate potential flaws, such as honeycombs and air pockets.

For slabs, concrete is left to stand until the surface moisture film disappears, then a wood or metal handfloat is used to smooth off the concrete. Floating produces a relatively even, but slightly rough, texture that has good slip resistance and is often used as a final finish for exterior slabs. If you need a smooth, hard, dense surface, follow floating by steel troweling.

Curing

Curing ensures the continued hydration of the cement so that the concrete continues to gain strength after placing. Start curing your concrete after its exposed surfaces have hardened enough to resist marring.

Cure concrete surfaces by sprinkling with water, fogging, or using moisture-retaining fabrics such as burlap or cotton mats. Other curing methods prevent evaporation of the water by sealing the surface with plastic or special sprays called curing compounds. During extremely cold or hot weather, special curing techniques.

-

Ready mixed concrete is often remixed once it arrives at the jobsite to ensure the proper slump is obtained. However, remixed concrete tends to set more rapidly than concrete mixed only once. Water, specific types of admixtures, and other materials are often added to the concrete at the jobsite after it has been batched to ensure the specified properties are attained before placement.

-

- For more information on ready mixed concrete, refer to the website of the National Ready Mixed Concrete Association.

Roller-Compacted Concrete

Roller-compacted concrete (RCC) is a stiff mix of aggregates, cement, and water. It is placed in layers with conventional earthmoving or paving equipment and compacted with vibratory rollers.

RCC Applications: RCC is used for mass concrete applications, such as dam construction, or when laying relatively thin, flat layers such as pavement. RCC is often used for large surfaces like parking lots.

-

Key Advantages

Simplicity: RCC construction is straightforward by nature.

Speed: RCC enables faster construction times compared to traditional methods.

Economy: RCC is cost-effective due to reduced material and labor requirements.Construction Advantages

RCC is a high-volume, high-speed construction method.

- No Joints Required

- No Formwork Needed

- No Finishing Needed

- No Steel Reinforcing Required

Environmental Advantages

While low cost, fast construction, and superior performance give RCC significant economic sustainability, its durability, resilience, and long lifespan also provide significant environmental benefits. Project teams can choose materials selection and construction methods that can reduce the carbon footprint and further improve the project’s environmental sustainability.

-

RCC shares the same basic ingredients as ready mixed concrete but has distinct characteristics that make it unique. It made from the following materials:

- Cement

- Water

- Aggregates: gravel or crushed stone

- Supplementary cementitious materials (SCMs) are sometimes included

- Chemical Admixtures are sometimes included

Unlike ready mixed concrete, RCC is a zero slump mixture, making it very stiff. The stiffness of RCC allows it to be compacted using vibratory rollers.

-

Blending: Normally, RCC is blended in continuous-mixing pugmills at or near the construction site. These high-output pugmills have the mixing efficiency needed to evenly disperse the relatively small amount of water used.

Laying: The RCC is then transported to the placement areas where it is spread out into a flat layer or lift between 4 and 12 inches thick.

Compaction: This is the most important stage of construction. It begins immediately after placement and continues until the RCC meets density requirements.

Curing: As with any type of concrete, curing makes moisture available for hydration, which is the chemical reaction that causes concrete to harden and gain strength. A water cure sprays or irrigates the RCC to keep it moist. A spray-on membrane can also be used to seal moisture inside the RCC, but is not appropriate for all applications.

-

Webinars to Watch

- Roller-Compacted Concrete for Pavements

- Applications of Roller-Compacted Concrete for Dams

- Design and Testing of Roller-Compacted Concrete

PDFs to Download

Pavements

- Subgrades and Subbases for Concrete Pavements

- Guide Specification for Construction of Roller Compacted Concrete Pavements

- Roller Compacted Concrete Pavements for Highways and Streets

- Production of Roller Compacted Concrete

- Frost Durability of Roller Compacted Concrete Pavements: Research Synopsis

- Thickness Design of a Roller Compacted Concrete Composite Pavement System

- Roller Compacted Concrete Pavements – A Study of Long Term Performance

- Effect of Density on Mechanical Properties and Durability of Roller Compacted Concrete

- Roller Compacted Concrete (RCC)

- Guide to Cement-Based Integrated Pavement Solutions

Water Resources

- Design Manual for RCC Spillways and Overtopping Protection

- Design Manual for Small RCC Dams

- Guide for Developing RCC Specifications and Commentary

- Roller-Compacted Concrete Quality Control Manual

- Roller Compacted Concrete (RCC)

- Facing Systems for Roller-Compacted Concrete Dams and Spillways

- Roller-Compacted Concrete Density: Principles and Practices

- Bonding Roller-Compacted Concrete Layers

- Dam Construction and Facing with Soil-Cement

- Erosion Abrasion Resistance of Soil-Cement and Roller-Compacted Concrete

- Buttressing an Aging Gravity Dam with RCC to Remedy Flood Risk

- New RCC Dam Replaces 70-Year Old Concrete Dam

- RCC Dam Saves City’s Sole Source of Water Supply

- Design/Build Approach Big Success for Pine Brook RCC Dam

- Hickory Log Creek RCC Dam and Reservoir Will Supply Much Needed Water

- Elkwater Fork Dam – A Reliable Source of Drinking Water

Concrete Pavement

Concrete has been used for more than a century to build long-lasting and low maintenance pavements. The earliest example, built in 1891, is still in service today. Concrete is a durable, economical and sustainable solution for many applications and all climates, from the freezing winters of the Upper Peninsula of Michigan to the scorching heat of the Southwest.

Common Applications:

- State highways

- Rural roadways

- Residential and city streets

- Intersections

- Airstrips

- Intermodal facilities

- Military bases

- Parking lots

-

There is a concrete solution for every type of roadway or pavement condition—from new pavements to reconstruction, resurfacing, restoration, and rehabilitation.

Concrete is the best solution for several reasons.

Long life: Concrete pavements have an average service life of 30 to 50 years.

Low maintenance requirements and costs: No need for repeated resurfacing, frequent spot repairs or patching.

Smoother traffic flow: The construction of concrete pavements does not require lengthy lane closures.

Quick reopening: Roads can be reopened in as short as six hours.

Low life-cycle cost: Consumes minimal materials, energy, and other resources for construction, maintenance, and rehabilitation activities throughout its service life.

Safety: Concrete pavement is less susceptible to the formation of heavy-vehicle wheel ruts, easier to see at night, ensures shorter vehicle stopping distances in wet weather, and due to longevity, requires fewer work zones over the life of the pavement.

-

- Plain pavements that use dowels to provide load transfer and prevent faulting.

- Plain pavements without dowels, in which aggregate interlock transfers loads across joints and prevents faulting.

- Conventionally reinforced pavements that contain steel reinforcement and use dowels in contraction joints.

- Continuously reinforced pavements that have no contraction joints and are reinforced with continuous longitudinal steel.

-

- The Subgrade. The subgrade—the native soil on which the pavement is built—must be graded and compacted. (In the fixed form method of paving, final preparation and shaping of the subgrade or subbase is completed after the forms are set; see below.)

- The Subbase. Preparation of the subgrade is often followed by the placing of a subbase—a layer of material that lies immediately below the concrete. The subbase prevents the displacement of soil from underneath the pavement. Subbases may be constructed of granular materials, cement-treated materials, lean concrete, or open-graded, highly permeable materials, stabilized or unstabilized.

- Reinforcement. Once the subbase has hardened sufficiently to resist marring or distortion by construction traffic, dowels, tiebars, or reinforcing steel are placed and properly aligned.

-

There are two methods for paving with concrete.

The Slipform Method

In slipform paving, a machine rides on treads over the area to be paved—similar to a train moving on tracks. Fresh concrete is deposited in front of the paving machine, which then spreads, shapes, consolidates, screeds, and float-finishes the concrete in one continuous operation. This operation requires close coordination between the concrete placement and the forward speed of the paver.

The Fixed Form Method

In fixed-form paving, stationary metal forms are set and aligned on a solid foundation and staked rigidly. Forms are first cleaned and oiled to ensure that they release from the concrete after the concrete hardens. Once concrete is deposited near its final position on the subgrade, spreading is completed by a mechanical spreader riding on top of the preset forms and the concrete. The spreading machine is followed by one or more machines that shape, consolidate, and float-finish the concrete. After the concrete has reached a required strength, the forms are removed and curing of the edges begins immediately.

-

After the concrete has been placed and finished, additional processes ensure the surfaces are strong, weather-resistant, and traffic-ready.

Cracking Control

As concrete pavement hardens, it contracts and cracks. Joints are created—typically by sawing—to control cracking. As the concrete continues to contract, the joints will open, providing room for the concrete to expand in hot weather and in moist conditions. In contraction joints that have been correctly designed and constructed, the cracks will occur below the joints.

After curing (see below) and once the pavement hardens, the joints are cleaned and sealed to exclude foreign material that would damage the concrete when it expands.

Texturing

Once joints have been inserted, the surface must be textured for skid resistance. This process should start just after the water sheen has disappeared and just before the concrete becomes non-plastic.

Texturing is done using burlap drag, artificial-turf drag, wire brooming, grooving the plastic concrete with a roller or comb equipped with steel tines, or a combination of these methods. The chosen method depends on the environment and the speed and density of expected traffic.

Curing

Curing begins immediately after finishing and as soon as the surface will not be marred by the curing medium.

The most common curing method uses white-pigmented liquid membrane curing compounds. Other, less typical methods include using waterproof paper or plastic covers such as polyethylene sheets, or wet cotton mats or burlap.

Opening to Traffic

After the specified curing period and when tests indicate that the concrete has reached the required strength, the pavement is prepared for opening: The shoulders are finished and the pavement is cleaned.

-

- Find more information on concrete pavement at the American Concrete Pavement Association.

- View or download a ACA fact sheet on Integrated Paving Solutions

High Performance and Ultra-High Performance Concrete

High performance concrete (HPC) and ultra-high performance concrete (UHPC) is engineered for performance that exceeds that of normal concrete. Attributes of HPC and UHPC may include high strength, high early strength, high modulus of elasticity, volume stability, and/or high durability.

Common Applications:

- Bridges

- Tall buildings

-

The main difference between high-strength and normal-strength concrete is the compressive strength. The American Concrete Institute defines HPC as concrete with a compressive strength greater than 6,000 psi. (There is no precise point of separation between high-strength and normal-strength concrete.)

HPC Use Cases

High-strength concrete is specified where reduced weight is important or architectural considerations call for small support elements. By carrying loads more efficiently than normal-strength concrete, HPC also reduces the total amount of material placed and lowers the overall cost of the structure.

HPC Production

The manufacture of high-strength concrete involves optimizing the basic ingredients found in normal-strength concrete. In addition to selecting high-quality portland cement, producers focus on optimizing the aggregates and adjusting the proportions of cement, water, aggregates, and admixtures.

Producing high-strength concrete mixtures requires the use of chemical admixtures. The most commonly used mineral admixtures in HPC are pozzolans, such as fly ash and silica fume. A common practice is to use a superplasticizer in combination with a water-reducing retarder. The superplasticizer improves the concrete’s workability at low water-cement ratios, resulting in greater strength. Meanwhile, the water-reducing retarder slows down the cement hydration process, giving workers more time to place the concrete.

-

There is no precise point of separation between high-strength concrete (HPC) and ultra-high-strength concrete (UHPC), also known as reactive powder concrete (RPC). However, UHPC has greater compressive strength and other superior properties compared to HPC.

UHPC has a minimum specified compressive strength of 17,000 pounds per square inch (120 MPa) and can be formulated to exceed 29,000 pounds per square inch (200 MPa).

UHPC Characteristics

Besides its strength, UHPC also meets specified requirements for durability, tensile ductility, and toughness. To achieve these specifications, fibers are typically included in the UHPC mixture.

- Ductile Behavior: UGPC exhibits ductile behavior— a first for concrete—allowing it to deform and support flexural and tensile loads even after initial cracking.

- Flexural strength: When combined with metal, synthetic, or organic fibers, it can achieve flexural strengths up to 7,000 psi (48 MPa) or greater.

- High compressive and tensile properties: These facilitate a high bond strength, enabling shorter rebar embedment lengths in applications such as closure pours between precast elements.

- Durability: The UHPC matrix is very dense, resulting in low permeability. This low permeability prevents the ingress of harmful materials such as chlorides, leading to superior durability.

- Simplified construction: UHPC construction is simplified by eliminating the need for reinforcing steel in some applications and by its high flow characteristics, which make it self-compacting.

- Aesthetics: The use of fine materials in the UHPC mixture creates a dense, smooth surface valued for its aesthetics and ability to closely transfer form details to the hardened surface.

UHPC Production

UHPC is typically formulated by combining portland cement, supplementary cementitious materials, reactive powders, limestone or quartz flour, fine sand, high-range water reducers, and water.

Fiber types often used in UHPC include high carbon steel, PVA, glass, carbon, or a combination of these types or others.

Some manufacturers have created just-add-water UHPC pre-mixed products, making UHPC more accessible. The American Society for Testing and Materials has established ASTM C1856/1856M, the Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete that relies on current ASTM test methods with modifications to make it suitable for UHPC.

Self-Consolidating Concrete

Self-consolidating concrete is a high-performance concrete that can flow easily into tight and constricted spaces without segregating or requiring vibration. The key to creating SCC, also referred to as self-compacting, self-leveling, or self-placing concrete, is a mixture that is fluid but also stable, to prevent segregation.

Mass Concrete

Mass concrete refers to any volume of concrete where a combination of the member’s dimensions, boundary conditions, concrete mixture characteristics, and ambient conditions can lead to undesirable thermal stresses, cracking, or harmful chemical reactions. These conditions reduce long-term strength. They can result from elevated concrete temperatures due to the heat of hydration (ACI 207.1R).

-

Mass concrete has traditionally been associated with large structures like dams and bridge piers. However, with the rise of fast-track construction and high-performance concretes with high cement content, mass concrete issues are now common in typical bridge and building projects. Understanding the causes of these issues, such as high internal temperatures and temperature-related cracking, is essential for building long-lasting structures.

-

These industry resources provide information on material selection, thermal control calculation methods, and construction practices for mass concrete placements.

- Mass Concrete for Buildings and Bridges, EB547

This document provides practical guidance on understanding mass concrete, managing concrete temperatures, and preventing or minimizing temperature-related cracking. - The ACI 207 – Mass and Thermally-Controlled Concrete Committee maintains several publications with more information.

- Mass Concrete for Buildings and Bridges, EB547

Precast Concrete

Precast concrete systems combine structural and architectural components to create long-lasting buildings and structures. From landmark bridges to high-rise office buildings, parking structures, stadiums and schools—even in high seismic zones—precast concrete can achieve safe, beautiful, and durable results that can also rank high for sustainability.

Common Applications:

- Parking Structures

- Stadiums and arenas

- Low- and mid-rise office buildings

- Apartment buildings

- Hotels and motels

- Nursing homes

-

Precast concrete elements are produced by casting concrete in a mold, which is then cured in a controlled environment, transported to the construction site, and maneuvered into place. The precast concrete elements can be produced from either dry mixture (vibrated or hydraulically pressed to consolidate/compact the material in molds) or from more fluid mixes to create shapes or panels.

-

Precast concrete’s benefits make it a material of choice for several types of applications.

Parking Structures

- The speed and ease with which precast structures can be built has helped make this material popular for parking structures.

- Precast concrete allows efficient, economical construction in all weather conditions and provides the long, clear spans and open spaces that parking structures need.

Stadiums and Arenas

- For stadiums and arenas, seating units and concrete steps can be mass produced according to specifications, providing fast installation and long-lasting service.

- Pedestrian ramps, concession stands, and dressing room areas can all be framed and constructed with precast concrete.

Buildings with Individual Units

- Precast concrete provides superior fire resistance and sound control for individual units and reduces fire insurance rates.

- The walls of the building can be manufactured while the on-site foundations are being built, providing significant time savings and resulting in early occupancy.

-

Precast systems are often used in sustainable or “green” buildings. In fact, concrete structures can qualify for a high number of points toward certification under the United States Green Building Council’s Leadership in Energy and Environmental Design (LEED®) Green Building Rating System.

- These systems use locally derived materials and can incorporate recycled supplementary cementitious materials like fly ash and slag cement.

- As with all concrete wall systems, precast offers high durability and strength as well as thermal mass, which contributes to increased energy efficiency.

-

- The Precast/Prestressed Concrete Institute (PCI) offers a broad spectrum of resources for architects and engineers, including design specifications for both architectural and structural applications.

- More information is available at the National Precast Concrete Association

Prestressed Concrete

Prestressing concrete members removes design limitations of conventional concrete by enabling the construction of longer, unsupported spans for roofs, floors, and walls. This allows architects and engineers to design and build lighter and shallower concrete structures without compromising strength. Prestressed concrete has seen considerable growth in the construction of commercial buildings.

Common Applications:

- Cast-in-place concrete

- Bridges

- Large girders

- Floor and roof slabs

- Shells

- Pavements

- Wall panels

- Railroad ties

-

Commercial Buildings. Prestressed concrete is ideal for shopping centers due to span length flexibility and internal structure alteration capabilities.

Institutional Buildings. It’s used in school auditoriums, gymnasiums, and cafeterias for its acoustical properties and its ability to provide long, open spaces.

Parking Garages. This is one of prestressed concrete’s most widespread uses due to the material’s structural advantages.

-

Imagine a row of books being moved from place to place. By compressing them horizontally, you can lift and carry them as a single unit. That is the principle behind prestressed concrete.

Conventional reinforced concrete uses steel’s tensile strength and concrete’s compressive strength to create a material that’s strong in both compression and tension. In prestressed concrete, the compressive stresses induced by high-strength steel tendons in a concrete member before loads are applied will balance the tensile stresses imposed in the member during service.

-

There are two methods of prestressing concrete.

Pretensioning

- Process: The steel is stretched before concrete placement.

- Steps:

- Stretch high-strength steel tendons between two abutments to 70–80% of their ultimate strength.

- Pour concrete into molds around the tendons and allow curing.

- Release stretching forces, translating tensile stresses into compressive stress in the concrete.

Post-Tensioning

- Process: The steel is stretched after the concrete hardens.

- Steps:

- Cast concrete around unstretched steel, often forming ducts using thin-walled steel forms.

- Once concrete hardens, insert and stretch steel tendons against the ends of the unit, anchoring them externally.

- This places the concrete into compression.

-

- The Precast/Prestressed Concrete Institute (PCI) offers a broad spectrum of resources for architects and engineers, including design specifications for both architectural and structural applications.

- More information is available at the National Precast Concrete Association

Tilt-Up Concrete

Tilt-up concrete gets its name from the construction method: Walls are cast in a horizontal position and then tilted vertically and moved into place with a mobile crane. Panels can be produced in many shapes and sizes, including flat and curved sections.

Tilt-up construction is rapid and economical. While it became popular for large, “big box” buildings with simple floor plans, new techniques with improved design flexibility have expanded the market, making tilt-up construction suitable for small buildings and those with more involved layouts.

Common Applications:

- Big box construction

- Schools

- Retail

- Commercial and civic projects

- Religious structures

- Residences

-

- Concrete placement is fast and easy because it is done on the ground. Floor surfaces can serve as casting beds, or separate casting beds may be built.

- Panels can be stacked on top of each other if space is limited.

- Because the panels are cast on site, their size is not limited by trucking considerations.

- Large panels can be made to limit the number of joints between the panels in buildings.

- Panels usually serve as structure and finish and can be insulated as needed for energy efficiency.

-

- Planning: The key to success in tilt-up construction is thorough planning.

- Concrete Ordering: Concrete is usually ordered from a ready mixed concrete producer, with mixes specified for high or early strength based on project needs.

- Placement:

- Concrete can be placed directly from the truck chute or by pump for precise placement.

- The concrete is then consolidated, trowel finished, and cured.

- Weather-dependent concreting procedures may apply since tilt-up panels are cast in the open.

- Casting and Lifting:

- Panels are cast face down on the slab.

- Once cured, they’re lifted and attached to the foundation or slab.

- Dowels into the slab and connections to adjacent panels provide structural integrity.

- Panels are braced during placement until all are secured together.

- Panels are lifted in quick succession, following a pre-planned schedule.

- Connections and Joint Treatment:

- Embedded connections in the concrete allow panels to be welded together.

- Vertical joints between panels are filled with sealants.

- Architectural Finishes:

- Architectural treatments enhance the appearance of panels.

- Common finishes include colored concrete, exposed aggregate, and form liner textures.

By following these steps, tilt-up construction ensures structural integrity, precise placement, and attractive architectural finishes.

-

Energy performance is an important part of tilt-up’s environmental friendliness.

- Like all concrete systems, tilt-up offers high thermal mass and airtight construction.

- The panelization means fewer joints and reduced air infiltration.

- Insulation can be incorporated into tilt-up to provide energy efficient construction with hard exterior wall surfaces. It is common to use extruded polystyrene at 2 to 6 inches thick. Walls can range from R-values of about 2 for uninsulated panels up to about 32 for walls containing thicker layers of insulation. As building codes require greater energy efficiency, the thickness of insulation increases.

All the other aspects of sustainability that apply to any type of concrete construction apply to tilt-up.

- There is potential for recycled content in tilt-up concrete. Wall panels can be demolished and the concrete recycled at the end of its life.

- Tilt-up is locally produced.

- It is durable and low maintenance.

-

- Tilt-up construction is covered by the International Building Code (IBC) in the reinforced concrete section. It is usually designed by a licensed structural engineer. (Tilt-up is not addressed in the International Residential Code (IRC).)

- The Tilt-Up Concrete Association (TCA) has design guides available.

- The ACI 551 – Tilt-Up Concrete Construction Committee maintains several publications with more information.

Architectural and Decorative Concrete

The term architectural concrete refers to concrete that serves a structural function while providing an aesthetically appealing finish. Decorative concrete is typically used for concrete flatwork or non-structural building elements that are enhanced with texture or color for aesthetic appeal. Both types of concrete are made to be seen. Whether you’re creating broad expanses or minute details, concrete permanently captures the look you want.

Common applications:

- Countertops

- Flooring

- Flatwork

Specific Types

- Self-Consolidating Concrete provides good form-filling characteristics and a quality finish, making it suitable for applications where appearance matters.

- Light-transmitting concrete can be used to fabricate translucent panels.

-

- Every cement has unique color tones due to slight differences in raw material ingredients and manufacturing processes. If a uniform color is critical in your design, consider stockpiling enough cement for the project.

- Cement gets its gray color from iron and manganese oxides. Because white portland cement contains negligible amounts of these compounds, it’s lighter in color. Use white cement in projects that demand lighter shades of concrete. Portland-limestone cement tends to be slightly lighter-colored than portland cement made from the same clinker, but factors other than the shade of cement also play a role in the color of concrete, including aggregate color and water content. White varieties of both portland cement and PLC may be available from various cement suppliers.

- Integrally colored concrete is made by adding mineral oxide pigments to concretes made with either white or gray cements. You can produce red, tan, and dark gray hues by using gray cement.

-

- A textured concrete surface will help camouflage the subtle differences in texture and color found on the surface of concrete.

- You can use forms and form liners to create textures and patterns that simulate, for example, brick, stone, and wood.

- Aluminum wall forming systems are available with brick-pattern faces, or with vertical rib or board-and-batten patterns.

Exposed Aggregate Surfaces

You can also use an exposed aggregate surface for textured effects. This is a decorative surface obtained by removing the outer layer of mortar and exposing the aggregate particles. Techniques used to expose aggregate particles include chemical surface retarders, sandblasting, water blasting, or acid etching.

Popular decorative aggregates may be natural materials such as quartz, granite, marble, limestone, and gravel or manufactured materials like alkali-resistant glass and ceramics. Select aggregates based on color, hardness, size, shape, gradation, durability, availability, method, and degree of exposure and cost.

Pervious Concrete

Pervious concrete is a special type of concrete with large openings that allows water to pass through, helping in stormwater management. Use of pervious concrete is among the Best Management Practices recommended by the EPA and other agencies for the management of stormwater runoff. Parking lot owners who use pervious concrete spend fewer dollars on stormwater management systems, and irrigation systems may be downsized or eliminated.

Pervious Concrete Applications: Parking lots and other areas of pavement, especially projects that involve stormwater management.

-

- Project cost: Pervious concrete can lower overall project costs on a first-cost basis and promote more efficient use of the land by eliminating the need for retention ponds, swales, and other stormwater devices.

- Operational costs: Can reduce operational costs and allow developers to increase use of available property.

- Lifecycle cost: Pervious concrete has a significantly lower life cycle cost due to its superior durability and strength, and longer life span than other alternatives.

- Reduced fees: Pervious concrete can help property owners minimize sewer system usage and avoid municipal stormwater impact fees.

- Aesthetics: Several options are available for enhancing pervious concrete’s aesthetics with treatments such as coloring, stamping, jointing, and grinding.

-

Pervious concrete is comprised of portland or blended cement, water, and uniformly sized aggregate falling within a narrow gradation. The aggregate gradation promotes the formation of open void areas in about 15% to 25% of the hardened mass. These allow for fast drainage of large volumes of water through the material.

Pervious concrete is part of a hydrologically designed stormwater management system, so the water passes through the material into the subgrade or subbase below, which may have a variety of treatment, conveyance and/or storage features.

Lean Concrete Base

A mix of aggregate and cement with less cement than regular concrete, lean concrete base is used to create a strong base layer. It’s spread and compacted like regular concrete.

-

Refer to these organizations for more information about LCB:

Types of Soil-Cement

Soil-Cement

Soil-cement (SC) is an engineered, densely compacted mixture of soil/aggregate, portland or blended cement plus, sometimes, other cementitious materials, and water. SC looks like regular soil when mixed, but when compacted, the cement binds the soil particles together, making it stronger and more durable. SC is known by various names, including cement-stabilized base, cement-treated aggregate base, cement-treated soil, and even dirtcrete. Regardless of what it is called, the principles governing its composition and construction are the same. On-site soils are amended to achieve the desired physical properties to build long-lasting, economical structures that have a low environmental impact over their lifespan.

-

Soil-Cement is used in numerous construction applications for pavements, water resources, and geotechnical projects.

Pavements applications include:

- Base courses for streets, roads, highways, shoulders, airports, and parking and storage areas

- Subbase courses for rigid pavements

- Modification or stabilization of subgrade soils

Water resources applications include:

- Slope protection for embankment dams, levees, and streambanks

- Liners for impoundments and channels

- In-stream grade control structures

Geotechnical applications include:

- Modification or stabilization of foundation soils

- Slurry cutoff walls

- Deep mixing methods

-

Four major variables control the engineering properties of SC materials:

- The characteristics of the soil

- The proportion of cement in the mix

- Moisture conditions (water content)

- The degree of compaction

The “soil” material in SC can be almost any combination of sand, silt, clay, gravel, or crushed stone. Local granular materials, such as slag, caliche, limerock, and scoria, plus a wide variety of waste materials including cinders, fly ash, foundry sands, and screenings from quarries and gravel pits, can all be used as soil material.

Learn More

For basic information on the influence of various soils on the design, construction, and performance of SC as well as considerable information on soil survey and sampling methods, see The ACA Soil Primer.

-

It’s important to carefully determine engineering control factors in the lab and their application during construction. That’s because variations in soil composition affect how soil reacts when combined with portland or blended cement and water.

Before starting construction, identify the soil that will be treated with cement and send representative samples of each soil type to a geotechnical lab for testing. (Note that testing can take some time, so plan accordingly.) State highway agencies and most commercial geotechnical labs can conduct these tests. They establish three fundamental requirements for soil-cement:

- The minimum cement content needed to achieve the desired strength and durability

- The optimum moisture content required to compact the soil-cement adequately

- The maximum dry density to which the soil-cement must be compacted during construction

Soil-Cement Testing Methods

To determine the three factors above, labs use established and current test methods from ASTM International (ASTM) and the American Association of State Highway and Transportation Officials (AASHTO).

Here is a summary of the more common ASTM and AASHTO specifications and test methods used in SC construction:

- ASTM C136 / AASHTO T 27 – Sieve Analysis of Fine and Coarse Aggregates

- ASTM C150 / AASHTO M 85 – Portland Cement

- ASTM C595 / AASHTO M 240 – Blended Hydraulic Cements

- ASTM C1157 – Performance Specification for Hydraulic Cement

- ASTM C1580 / AASHTO T 290 – Water-Soluble Sulfate in Soil

- ASTM C1602 – Mixing Water Used in the Production of Hydraulic Cement Concrete

- ASTM D558 / AASHTO T 134 – Moisture-Density (Unit Weight) Relations of Soil-Cement Mixtures

- ASTM D559 / AASHTO T 135 – Wetting and Drying Compacted Soil-Cement Mixtures

- ASTM D560 / AASHTO T 136 – Freezing and Thawing Compacted Soil-Cement Mixtures

- ASTM D1633 – Compressive Strength of Molded Soil-Cement Cylinders

- ASTM D4318 / AASHTO T 90 – Liquid Limit, Plastic Limit, and Plasticity Index of Soils

- ASTM D6913 / AASHTO T 88 – Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis

Learn More

For more detailed information about specific testing procedures, refer to the ACA Soil-Cement Laboratory Handbook.

-

Stabilized Cement used in pavements, water resources, and geotechnical projects can be mixed either on-site or at a nearby central mixing plant. Central mixing plants are a better choice when using borrow materials or material blends.

Each type of material has its advantages, and selection is based on application: friable granular materials for their low cement requirements and ease of handling and mixing; pugmill-type mixers for their speed, mixing efficiency, and continuous production.After mixing, the SC is transported to the job site in dump trucks and spread on the prepared subgrade, subbase, or embankment. The compaction and curing procedures are the same regardless of whether the SC is mixed on-site or at a central plant.

Soil-Cement Construction Objectives

The goal in SC construction is to create a thoroughly mixed, adequately compacted, and properly cured material. The construction process is straightforward and involves five steps:

- Preparing

- Shape the area to the required plan elevations (crown, grade, slope, etc.).

- Correct any unstable subgrade, subbase, or embankment areas.

- If necessary, scarify, pulverize, pre-wet the soil, and reshape to plan elevations.

- Processing

- Mixed-in-place method

- Distribute portland or blended cement (dry or slurry) and mix.

- Apply water and remix.

- Central mixing plant method

- Mix soil, portland or blended cement, and water.

- Haul mixed soil-cement to the placement area.

- Spread SC uniformly over the placement area

- Mixed-in-place method

- Compacting

- Finishing

- Curing

Most SC materials require minimal preliminary pulverizing, typically done the day before processing. Processing operations are continuous and should be completed the same working day.

Equipment Used in SC Construction

The construction of SC uses various common roadway and sitework machinery. Equipment may vary by contractor, but the basic machinery includes:

- Soil mixer/reclaimer

- Motor grader

- Dry cement spreader or slurry spreader/distributor truck

- Water truck

- Compaction equipment

- Tamping/sheepsfoot/padfoot roller (for clayey and silty material)

- Smooth drum roller (for granular soils)

- Pneumatic tire roller (optional)

Key Considerations

When SC is properly mixed with the correct cement content and compacted to its maximum dry density, the mixture becomes permanently bonded. The hardened soil-cement will not deform or consolidate further under loading. Curing is crucial to prevent water evaporation and ensure maximum strength development through cement hydration. Contractors expect soil-cement projects to be relatively straightforward, with minimal weather delays and no need to rework completed sections.

Field Inspection and Control

Field inspection and control during SC construction focus on ensuring the correct cement content, moisture content, mixing, compaction, and curing. This ensures the project meets the specified requirements, and any issues can be addressed immediately.

Learn More: Detailed inspection steps and relevant tables and charts are available in the ACA Soil-Cement Inspector’s Manual.

- Preparing

Cement-Modified Soil

Cement-modified soil (CMS) is a mix of soil, water, and a small amount of cement. This creates a material that is easier to work with and less affected by moisture compared to untreated soil.

CMS Applications: CMS helps extend the life of pavements or structures by providing uniform support through a durable, stable, and typically non-expansive subgrade or foundation.

-

- Improves workability of subgrade soils for construction purposes.

- Reduces plasticity and shrink/swell volume change potential.

- Reduces moisture susceptibility and migration.

- Accelerates construction due to reduced rain impact.

- Increases bearing capacity compared to untreated soil.

- Promotes soil drying.

- Enhances working platform.

- Cost-effective: Use of on-site soil avoids costly removal and replacement with select fill material.

- Offers permanent soil modification without leaching.

- No mellowing period required

-

CMS involves treating in situ soils with a relatively small proportion of portland or blended cement. This treatment provides a material similar to soil but with less plasticity and lower susceptibility to moisture, making it more workable and stable.

-

- Properties and Uses of Cement-Modified Soil

- Soil-Cement for Commercial Sites

- The ACA Soil Primer

- Guide to Cement-Based Integrated Pavement Solutions

- Soil-Cement Laboratory Handbook

- Soil-Cement Inspector’s Manual

- Evaluating the Performance of Soil-Cement and Cement-Modified Soil for Pavements: A Laboratory Investigation

- Performance of Cement-Modified Soils: A Follow-Up Report

- Evaluation of Laboratory Durability Tests for Stabilized Subgrade Soils

- Slurry Stabilization and Reaction Chemistry Of Cement-Treated Soils

Cement-Stabilized Subgrade Soil

Cement-stabilized soil (CSS) is a stronger mix of in situ soil, water, and more cement than CMS. It results in a material with substantially increased stiffness and strength, as well as providing all the benefits of CMS.

CSS Applications: CSS provides measurable structural benefits to pavement and building foundations.

-

In addition to all the benefits of CMS, CSS also provides the following:

- Fully engineered material

- A semi-bound to bound material

- Typical 7-day unconfined compressive strengths (UCS) from 100 to 300 psi (0.7 to 2.1 MPa)

- A potential reduction in pavement or foundation thickness or increased service life

-

The degree of improvement provided by CSS depends on the quantity of cement used and the type of soil. By adding varying amounts of cement, you can produce cement-stabilized subgrade with a wide range of engineering properties.

-

- Guide to Cement-Stabilized Soils

- Properties and Uses of Cement-Modified Soil

- Soil-Cement for Commercial Sites

- The ACA Soil Primer

- Guide to Cement-Based Integrated Pavement Solutions

- Soil-Cement Laboratory Handbook

- Soil-Cement Inspector’s Manual

- Evaluating the Performance of Soil-Cement and Cement-Modified Soil for Pavements: A Laboratory Investigation

- Performance of Cement-Modified Soils: A Follow-Up Report

- Evaluation of Laboratory Durability Tests for Stabilized Subgrade Soils

- Slurry Stabilization and Reaction Chemistry Of Cement-Treated Soils

Cement-Treated Base

Cement-treated base (CTB) is a mix of native soils and/or manufactured aggregates with measured amounts of portland or blended cement and water, which hardens after compaction and curing.

CTB Applications: CTB forms a strong, long-lasting layer often used under roads.

-

CTB construction can achieve durable and long-lasting road bases. Its benefits:

- Imperviousness: Hard, rigid CTB resists cyclic freezing, rain, and spring-weather damage.

- Durability: CTB continues to gain strength with age, even under traffic, providing reserve strength that contributes to its excellent performance.

-

Your objective in CTB construction is to achieve a thorough mixture of aggregate/granular material with the correct quantity of portland or blended cement and sufficient water to allow for maximum compaction. The completed CTB must be adequately cured to allow the cement to hydrate and harden the cement-aggregate mixture.

Fundamental Control Factors for Quality CTB

- Proper cement content

- Adequate moisture content

- Thorough mixing

- Adequate compaction

- Proper curing

Mixing Methods

The aggregate/granular material, cement, and water are typically mixed in a central mixing plant. These plants can be:

- Continuous-flow pugmill mixers

- Batch-type pugmill mixers

Alternatively, CTB can be mixed in place using:

- Transverse-shaft pulver mixers

- Traveling mixing machines

Thickness and Load Distribution

CTB requires less thickness compared to granular bases for the same traffic load, because it is a cemented, rigid material. This rigidity allows CTB to distribute the load over a larger area. Its slab-like characteristics and beam strength are superior to granular bases, which can fail if CTB requires less thickness compared to granular bases for the same traffic load because it is a cemented, rigid material. This rigidity allows CTB to distribute the load over a larger area. Its slab-like characteristics and beam strength are superior to granular bases, which can fail if wet subgrade soil is forced up into the base by traffic loads, and interlock is lost.

-

Webinars to Watch

PDFs to Download

- Soil-Cement Laboratory Handbook

- Guide to Cement-Treated Base (CTB)

- Guide to Cement-Based Integrated Pavement Solutions

- Reflective Cracking in Cement Stabilized Pavements

- Performance of Soil-Cement and Cement-Modified Soil for Pavements: Research Synopsis

- Microcracking

- Soil-Cement Inspector’s Manual

- Soil-Cement for Commercial Sites

- Evaluating the Performance of Soil-Cement and Cement-Modified Soil for Pavements: A Laboratory Investigation

- Minimizing Cracking in Cement-Treated Materials for Improved Performance

- Soil Stabilization Field Trial

- Thickness Design Systems for Pavements Containing Soil-Cement Bases

- Evaluation of Laboratory Durability Tests for Stabilized Aggregate Base Materials

- Effects of Environmental Factors on Construction of Soil-Cement Pavement Layers

- Slurry Stabilization and Reaction Chemistry Of Cement-Treated Soils

Full-Depth Reclamation

Full-depth reclamation (FDR) with cement is a process where an old, damaged asphalt road is ground up and mixed with cement, then compacted to form a new, stabilized base layer. Because this technique recycles deteriorated road surfaces, it is both cost-effective and environmentally friendly.

FDR Applications: Road resurfacing

-

- Cost Savings: FDR with cement reduces expenses by minimizing the need for new construction materials.

- Environmental Impact: The process lowers the carbon footprint by cutting down on mining, hauling, and disposal activities.

- Stability: The result is a stiff, stabilized base layer suitable for a new bituminous or concrete surface.

-

- Pulverization: The existing roadway materials are pulverized in place.

- Mixing: Portland or blended cement and water are uniformly mixed with the pulverized materials.

- Compaction: The mixture is compacted using rollers.

- Shaping: Motor graders shape the compacted layer.

- Curing: Proper curing is carried out to ensure the stability of the new base layer.

-

Webinars to Watch

PDFs to Download

- Guide to Full-Depth Reclamation with Cement

- Guide to Cement-Based Integrated Pavement Solutions

- Soil-Cement Laboratory Handbook

- Reflective Cracking in Cement Stabilized Pavements

- Long-Term Performance of Full-Depth Reclamation with Portland Cement: Research Synopsis

- Performance of Soil-Cement and Cement-Modified Soil for Pavements: Research Synopsis

- Microcracking

- Soil-Cement Inspector’s Manual

- Soil-Cement for Commercial Sites

- Evaluating the Performance of Soil-Cement and Cement-Modified Soil for Pavements: A Laboratory Investigation

- Minimizing Cracking in Cement-Treated Materials for Improved Performance

- Thickness Design Systems for Pavements Containing Soil-Cement Bases

- Evaluation of Laboratory Durability Tests for Stabilized Aggregate Base Materials

- Effects of Environmental Factors on Construction of Soil-Cement Pavement Layers

- Slurry Stabilization and Reaction Chemistry Of Cement-Treated Soils

- Full-Depth Reclamation using Portland Cement: A Study of Long-Term Performance

- Full-Depth Reclamation: Recycling Roads Saves Money and Natural Resources

Other Common Cement Applications

See how various types of cement and cementitious materials can be used in the following applications.

Lightweight Cellular Concrete

A lightweight mix of cement, water, and air bubbles, lightweight cellular concrete (LCC) is used as a fill material. It’s easy to pour and levels itself out.

Common Applications:

LCC can act as a lightweight, strong, durable, and inexpensive soil or fill replacement for a multitude of geotechnical applications.

-

LCC is popular in geotechnical applications for several reasons:

- It is lighter in weight than soil.

- It is highly flowable and able to fill spaces of any size and shape.

- It is less expensive than many alternatives.

- It can be produced and placed on site, making it a great solution to help lower the carbon footprint of a jobsite by drastically reducing the volume of material transported to reduce carbon emissions and keep job sites less congested.

-

LCC is a mixture of portland or blended cement, water, and air created through a preformed foaming agent.

LCC in the geotechnical environment can be used for multiple purposes including lightweight road bases and fills, bridge approach embankments, void and cavity filling, pipe and culvert abandonment filling, annular space tunnel grout filling, foundation fills, energy arresting systems, retaining wall backfills, lightweight dam and levee structural fills, landslide repair and slope stabilization, and as controlled density fill.

-

ACA, in collaboration with the National Pavement Technology Center and Iowa State University Institute of Transportation, has created a downloadable Guide to Lightweight Cellular Concrete for Geotechnical Applications.

Flowable Fill

Also known as controlled low-strength material (CLSM), controlled density fill (CDF), flowable mortar, plastic soil-cement, and soil-cement slurry, this is a self-leveling and self-consolidating concrete material. Traditional flowable fills are mixtures of portland or blended cement, water, fly ash, fine aggregate, and air.

Flowable Fill Applications: This material is used mainly as backfill.

Learn More: For more information about flowable fill, refer to the National Ready Mixed Concrete Association.

Concrete Masonry Units

Concrete masonry units (CMU) are segmental concrete products made from concrete mixtures placed into molds. Because CMUs are favored for their efficiency and cost-effectiveness in constructing various low-rise residential and commercial buildings, factories across the country produce these units, supporting local economies and providing locally available resilient building materials.

Common Applications:

- Low-rise residential buildings

- Educational facilities

- Commercial structures

- Industrial buildings

-

Design and Construction Advantages

- Structural versatility: CMUs can be reinforced as needed to meet demanding structural applications, providing flexibility in design and construction.

- Attractive finish: Often preferred by architects for their aesthetic appeal, CMUs can provide an exposed, durable finish without the need for additional treatments.

- Space-efficient construction: CMU construction does not require a large staging area, which is advantageous for space-constrained sites.

- Readily available materials: CMU materials are typically available “off the shelf,” minimizing the likelihood of construction delays due to material shortages.

Sustainable and Resilient

- Non-combustible and durable: CMUs are inherently fire-resistant and provide a tough exterior, making them suitable for demanding environments.

- Environmental benefits: CMUs can contain recycled materials, do not emit volatile organic compounds, and avoid potentially harmful off-gassing materials.

- Energy efficiency: The thermal mass of CMUs helps maintain uniform temperatures within a structure, enhancing energy efficiency.

- Material Conservation: CMUs make efficient use of cement, with a low content for each block while maintaining strength and performance.

- Carbon Uptake: Among all cement-based materials, CMUs carbonate the fastest, reducing the overall carbon footprint of the project.

-

Concrete masonry units are manufactured from very dry, stiff concrete mixtures. These “no-slump” or “low-slump” materials are placed into molds, vibrated, compacted, and quickly demolded. The units are then cured and palletized in preparation for shipping.

Over the past century, the manufacturing process has evolved from hand-casting to high-tech automated systems, resulting in excellent quality control, uniformity, and speed for high-volume production.

-

Wall Systems

CMUs are modular, with the most common size being a nominal 8-by-8-by-16 inches. Units are held together by mortar, and designers position door and window openings to minimize cutting of units.

There are three CMU wall types:

- Single Wythe: Walls containing one vertical layer of units.

- Double Wythe: Walls with two vertical layers of units.

- Cavity Wall: When wythes are separated by a continuous vertical space.

Reinforcement allows CMU wall systems to be customized for the structural loads and exposure conditions of any site, including wind and seismic forces: Reinforcement is placed into horizontal and vertical cavities as needed, with cement-based grout infilled around it.

Insulation may be added to interior or exterior faces, between wythes, or inside special unit cavities to complement the thermal mass of walls for improved energy efficiency.

Other accessories may be needed to promote proper drainage, attach finishes, and complete the wall.

Finishes

- Simplified Finishes: CMU walls are extremely versatile in appearance, whether using plain or architectural units. Options include sealing, painting, or plastering for aesthetics and improved moisture resistance. In many cases, masonry is left exposed on one or both faces.

- Durable Finishes: Some finishes are made specifically for durability in moist exposures, such as locker rooms, pools, kitchens, or laundry facilities. These masonry surfaces are often brightly colored to provide a tough, attractive finish.

-

Masonry has its own design and construction code. The Building Code Requirements and Specification for Masonry Structures is published by The Masonry Society. These companion standards and their commentaries are written in mandatory language and become code when adopted by an authority having jurisdiction. They address materials, labor, design, and construction.

-

Many helpful tools for the design and construction of masonry are available.

- The National Concrete Masonry Association has online technical publications known as TEK sheets and details for concrete masonry.

- The Brick Industry Association also publishes technical notes for clay masonry.

- A number of other groups such as The Masonry Society publish guides and other documents used for the design and construction of masonry.

Stucco

Stucco—the common term for portland cement plaster—is a popular exterior finish for buildings. It provides a surface that is rot, rust, and fire resistant, and that can be colored and finished in a wide range of textures.

Common Applications:

Exterior cladding for a variety of building types.

-

- Cost-Effective: Stucco is an economical exterior cladding option.

- Durable: Stucco is tough, resilient, and fire-resistant, making it a long-lasting finish.

- Water Resistant: Properly installed stucco over concrete masonry effectively resists water penetration.

- Versatile: It offers a variety of colors and textures to enhance the aesthetic appeal of buildings.

-

Stucco is a mixture of cementitious ingredients, aggregate, and water, with other materials sometimes added to enhance its performance. Options for cementitious ingredients include general purpose cements, as well as “plastic” cements made for plastering applications and masonry cements for mortar applications, both of which may have lower carbon footprints than general use cements.

Installation

- Stucco is commonly attached to framed walls with metal lath but can also be applied directly to concrete and masonry.

- Stucco is an effective finish for resisting water penetration. Industry practices (like ASTM C 926) provide guidance for the proper proportioning and installation of plaster.

Color and Texture

- Color: The color of stucco is determined by the cement and aggregate color and can be modified by adding mineral oxide pigments. White portland cement allows for a wide range of colors, including bright white. Factory-prepared finish coat products often contain white cement and pigments for ease of use.

- Texture: Special treatment techniques during and after application can impart various textures to the plaster surface, to mimic the look of different construction materials like wood timbers, brick, or stone masonry.

-

Guides for the installation and repair of stucco are available in the ACA store.

Insulating Concrete Forms

Insulating concrete form systems (ICFs) are a builder-friendly wall system consisting of stay-in-place formwork and concrete. Lightweight foam blocks or panels are assembled in the shape of a building’s walls, reinforced, then filled with concrete to result in cast-in-place concrete walls that are sandwiched between two layers of insulation. ICF walls are air-tight, strong, pest and fire-resistant, and durable in harsh weather conditions. ICF buildings offer superior energy and sound-blocking efficiency for quiet, comfortable interiors.

Common Applications:

- Low-rise buildings for residential, commercial, and industrial properties. Common uses are single-family homes, hotels, schools, churches, shopping centers, and warehouses.

- Architectural Appearance: Interior and exterior faces can be finished with traditional materials, making ICF buildings look similar to typical construction, though with thicker walls.

-

- Durable: ICF walls are strong, air-tight, and durable against harsh weather conditions.

- Pest and fire-resistant, enhancing building safety.

- Easy to install: Quick and easy to install using common construction tools and equipment.

- Versatile: A wide variety of manufacturers, shapes, and sizes allows for custom design of smaller commercial structures.

- A green material: Some products incorporate recycled materials, contributing to green construction efforts.

- Energy efficient: ICF walls are highly insulated, providing superior energy efficiency and comfort. Special units and reversible forms improve the efficiency of construction and the energy performance of the final structure.

-

Design and Installation:

Form Types

The three ICF form shapes result in different wall types:

- Flat systems yield a uniform thickness of concrete, similar to conventionally poured walls.

- Grid systems produce a waffle pattern where the concrete is thicker at some points than others.

- Post and beam systems feature discrete horizontal and vertical columns of concrete encapsulated in foam insulation.

Materials

- Foam types are most often expanded polystyrene (EPS) but can be extruded polystyrene (XPS) for greater strength at a higher cost. Some products use recycled foam or wood fiber for even “greener” construction.

- Connectors/ties are made from plastic, metal, or additional projections of the insulation. Hinged ties allow for preassembled forms to be flattened for easier, less costly shipping.

Construction Processes

- Assembly: Blocks, panels, or planks are shipped to the site for assembly in place.

- Joint Configurations: Interlocking teeth, tongue and groove, or simple butt-jointed seams. Reversible forms save time and ensure proper alignment.

- Special Units: Some manufacturers offer special shapes for easier construction of corners, floors, and roofs, improving system engineering, speed of assembly, and energy efficiency.

-

From a sustainability viewpoint, the energy efficiency, long service life, and potential use of local, recycled materials make ICF construction environmentally beneficial.

Energy Efficiency

Insulating concrete form systems’ potential for creating energy-efficient structures is a major draw. Some estimates place the energy savings at 20% or more. (The R-value for a typical ICF is about 20.)

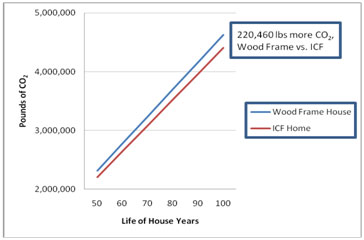

ICF walls can be 10% to 30% more air-tight than frame walls—with compatible windows, doors, and roofs. As a result, assuming a 100-year service life, one single-family ICF home has the potential to save about 110 tons of CO2 compared to a traditional wood frame home. This more than offsets the CO2 associated with the production of the cement used to make the concrete.

Thermal mass is one reason insulating concrete forms work so well to maintain a consistent temperature; insulation is the other. This saves quite a bit of energy associated with heating and cooling and also provides a more comfortable interior.

Other Sustainability Factors

- ICFs save trees because the wood frame is eliminated.

- Concrete can be made using supplementary cementitious materials like coal ash or slag to replace a portion of the cement.

- ICFs systems has the potential to contain recycled materials, such as recycled aggregate (from crushed concrete) and recycled polystyrene.

-

The Insulating Concrete Form Manufacturers Association represents the ICF industry in North America and provides many types of resources for ICF construction.

- Structural Design of Insulating Concrete Form Walls in Residential Construction, EB212

- This engineering manual provides design procedures for residential structures built using ICF wall systems. It includes a step-by-step method for designing homes with ICF walls and demonstrates the design procedure with a comprehensive example. It also provides design aids in the form of graphs, charts, and tables.

- Structural Design of Insulating Concrete Form Walls in Residential Construction, EB212