Thermal mass is a property that enables building materials to absorb, store, and later release significant amounts of heat. Early civilizations took advantage of thermal mass properties in stone and adobe construction to enable life in very hot and dry climates centuries ago. Buildings constructed of concrete and masonry have the same energy-saving advantage because of their inherent thermal mass. These materials absorb energy slowly and hold it for much longer periods of time than do less massive materials. This delays and reduces heat transfer through a thermal mass building component, leading to three important results:

Thermal mass is a property that enables building materials to absorb, store, and later release significant amounts of heat. Early civilizations took advantage of thermal mass properties in stone and adobe construction to enable life in very hot and dry climates centuries ago. Buildings constructed of concrete and masonry have the same energy-saving advantage because of their inherent thermal mass. These materials absorb energy slowly and hold it for much longer periods of time than do less massive materials. This delays and reduces heat transfer through a thermal mass building component, leading to three important results:

- There are fewer spikes in the heating and cooling requirements, since mass slows the response time and moderates indoor temperature fluctuations.

- For climates with a large daily temperature swing, a thermally massive building uses less energy than a similar low mass building due to the reduced heat transfer through the massive elements.

- Thermal mass can shift energy demand to off-peak time periods when utility rates are lower. Since power plants are designed to provide power at peak loads, shifting the peak load can reduce the number of power plants required.

The thermal mass of concrete has the following benefits and characteristics:

- Delays peak loads

- Reduces peak loads

- Reduces total loads in many climates and locations

- Works best in commercial building applications

- Works well in residential applications

- Works best when mass is exposed on the inside surface

- Works well regardless of the placement of mass

Mass works well in commercial applications by delaying the peak summer load, which generally occurs around 3 p.m. to later when offices begin to close. As a case in point, a large scale blackout in the Northeast United States occurred at 3 p.m. on August 2003 as power plants were unable to supply the demand from operational and heat, ventilation and air conditioning (HVAC) loads. More mass in building construction would have delayed this HVAC demand to later in the day, and may have prevented this peak power problem.

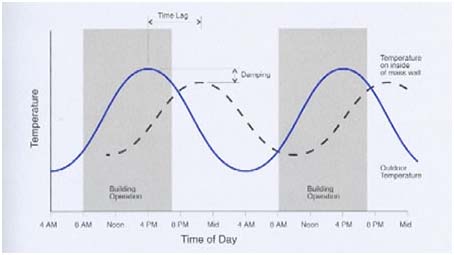

Damping and lag effect thermal mass

The ASHRAE Standard 90.1–Energy Standard for Buildings Except Low-Rise Residential Buildings, the International Energy Conservation Code, and most other energy codes recognize the benefits of thermal mass and require less insulation for mass walls.

In some climates, thermal mass buildings have better thermal performance than low mass buildings, regardless of the level of insulation in the low mass building. The most energy is saved when significant reversals in heat flow occur within a wall during the day. So, mass has the greatest benefit in climates with large daily temperature fluctuations above and below the balance point of the building (55 to 65 degrees Fahrenheit). For these conditions, the mass can be cooled by natural ventilation during the night, and then be allowed to absorb heat or "float" during the warmer day. When outdoor temperatures are at their peak, the inside of the building remains cool, because the heat has not yet penetrated the mass. Although few climates are this ideal, thermal mass in building envelopes will still improve the performance in most climates. Often, the benefits are greater during spring and fall, when conditions most closely approximate the "ideal" climate described above. In heating-dominated climates, thermal mass can be used to effectively collect and store solar gains or to store heat provided by the mechanical system to allow it to operate at off-peak hours.

Thermal resistance (R-values) and thermal transmittance (U-factors) do not take into account the effects of thermal mass, and by themselves, are inadequate in describing the heat transfer properties of construction assemblies with significant amounts of thermal mass. Only computer programs such as DOE-2 and EnergyPlus that take into account hourly heat transfer on an annual basis are adequate in determining energy loss in buildings with mass walls and roofs. The heat flow through the wall is dependent on the materials’ unit weight (density), thermal conductivity, and specific heat.

Specific Heat and Heat Capacity

Specific heat is defined as the amount of heat energy (in British thermal units (btu)) required to raise the temperature of one pound of a material by one degree Fahrenheit. Specific heat describes a material's ability to store heat energy. The specific heat of concrete and masonry can generally be assumed to be 0.2 British thermal units per pound degrees Fahrenheit (Btu/lb·°F). (ASHRAE Handbook of Fundamentals, 2005)

Heat Capacity (HC) is the amount of heat energy required to raise the temperature of a mass one degree Fahrenheit. Heat capacity is per square foot of wall area (Btu/ft2·°F) and includes all layers in a wall. For a single layer wall, HC is calculated by multiplying the density of the material times its thickness (in feet) times the specific heat of the material. Heat capacity for a multilayered wall is the sum of the heat capacities for each layer.

Values of heat capacity, thermal resistance, and thermal transmittance for concrete and masonry are presented in Appendix A of

ASHRAE Standard 90.1-2004. Thermal conductivities are presented in the

ASHRAE Handbook of Fundamentals. Thermal Mass modeling studies are highlighted under "Energy Models" Under the Tools menu. Full reports are listed here as resources as well.

Concrete: The Choice for Sustainable Design

Concrete's Contribution to Sustainable Development

Concrete is the most widely used building material on earth. It has a 2,000 year track record of helping build the Roman Empire to building today's modern societies. As a result of its versatility, beauty, strength,·and durability, concrete is used in most types of construction, including homes, buildings, roads, bridges, airports, subways, and water resource structures. And with today's heightened awareness and demand for sustainable construction, concrete performs well when compared to other building materials. Concrete is a sustainable building material due to its many ecofriendly features. The production of concrete is resource efficient and the ingredients require little processing. Most materials for concrete are acquired and manufactured locally which minimizes transportation energy. Concrete building systems combine insulation with high thermal mass and low air infiltration to make homes and buildings more energy efficient. Concrete has a long service life for buildings and transportation infrastructure, thereby increasing the period between reconstruction, repair, and maintenance and the associated environmental impact. Concrete, when used as pavement or exterior cladding, helps minimize the urban heat island effect, thus reducing the energy required to heat and cool our homes and buildings. Concrete incorporates recycled industrial byproducts such as fly ash, slag, and silica fume that helps reduce embodied energy, carbon footprint, and waste.

References

Energy Use of Single-Family Houses With Various Exterior Walls (2001), J. Gajda, R&D Serial No. 2518, 50 pages

Available for free. A typical 2,450 square-foot single-family house with a current design was modeled for energy consumption in 25 locations across the United States and Canada. Locations were selected to represent a range of climates. Energy simulation software utilizing the DOE 2.1E calculation engine was used to perform the modeling.

2014 ASHRAE Handbook - Fundamentals ASHRAE

The 2014 volume of the ASHRAE Handbook covers basic principles and provides essential data for HVAC&R design covering general engineering information, basic materials, load and energy calculations and duct and pipe design.

Radiant Flooring Guide, Radiant Panel Association

Available for download for free. This publication is designed to help homeowners and building designers understand their choices. It includes information on how radiant floors work, how to include radiant floor in your design, hydronic (hot water) and/or electric, product directory, gallery of radiant systems, resource guide, selecting floor coverings for radiant floors: wood, decorative concrete, tile, stone, marble, carpet, laminate flooring, resilient flooring.

Standard 90.1-2013 - Energy Standard for Buildings Except Low-Rise Residential Buildings (2013) ASHRAE

This standard provides the minimum requirements for energy-efficient design of most buildings, except low-rise residential buildings. It offers, in detail, the minimum energy-efficient requirements for design and construction of new buildings and their systems, new portions of buildings and their systems, and new systems and equipment in existing buildings, as well as criteria for determining compliance with these requirements. It is an indispensable reference for engineers and other professionals involved in design of buildings and building systems.

An Engineers Guide to: Economical Concrete Floor Systems (2005)

This 6-page bulletin presents information on cast-in-place reinforced concrete floor systems. The publication includes guidelines for selecting different floor systems for virtually any span and loading condition. The emphasis is on selecting cost-effective slab system for different situations. Also included are design aids for preliminary thickness estimation. The floor systems covered are; flat plate, flat slab, one-way joist, wide-module joist, two-way joist, and banded-beam. In addition information on drop panel, form work details, standard form dimensions for one-way and two-way joist construction is also included.

Comfort and Quiet with Concrete Homes, IS305, (2005)

This document highlights the benefits derived from combining the mass of concrete with the insulating value of insulating forms. Together they provide a home that lessens the intrusion of outside noise, while improving the thermal performance of the home. PDF.