Grout cleanouts, which the contractor uses to prepare the space for grouting, allow inspectors to verify that reinforcement has been properly placed and tied.

Building codes for masonry, as for all types of construction, establish minimum requirements to assure public safety. In the United States, the

International Building Code (IBC) references the Masonry Standards Joint Committee (MSJC)

Building Code Requirements and Specification for Masonry Structures (TMS402/ACI 530/ASCE 5 and TMS 602/ACI 530.1/ASCE 6).

Because contemporary masonry construction can be more highly detailed than in the past and because it continues to evolve, it is increasingly important to have a quality assurance (QA) program in place. This is the overall plan for verifying construction and it’s how compliance with contract documents is verified.

Inspection is one aspect of a QA program and ensures that builders are doing what the designer intended, and ultimately, that the owner is getting what they paid for. For masonry, “special inspection” lays out specific requirements for activities and frequency of them to ensure quality in construction.

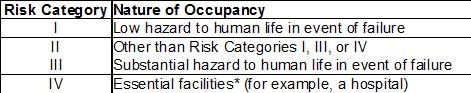

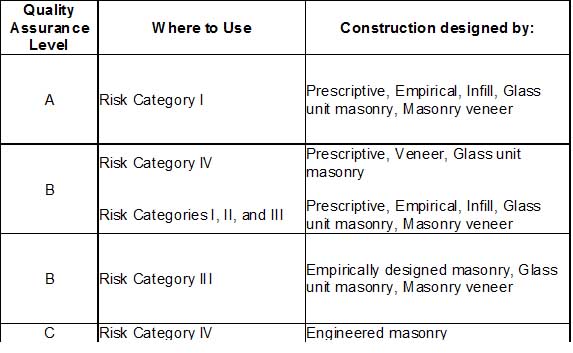

The level of inspection for masonry construction is based on both the facility importance (Risk Category) and the design procedure, such as engineered masonry. There are four Risk Categories―I, II, III, and IV―and there are three levels of quality assurance provisions―Level A, Level B, and Level C.

Level A is the least stringent level and Level C is the most rigorous, but owners or designers can choose to increase inspections requirements if they desire. Since requirements are progressive, Level B requires that you also meet Level A requirements and Level C requires that you meet requirements of both Level A and B.

The Role of Inspectors

Special inspectors are the people who have the training and knowledge to look at masonry walls as they are constructed to assure that they are being built according to plan. For instance, inspectors are trained to look for unobstructed grout spaces, how to check the placement of reinforcement, and how to test mortar and grout. They watch over construction as it proceeds to see that contractors are doing things right.

Qualified inspectors are needed to implement effective inspection programs. Two aspects of meeting that need are training and certification of masonry inspectors. Training programs for masonry inspectors include various local masonry groups and national organizations such as The Masonry Society (TMS). Certification can be obtained through The International Codes Council (ICC), publisher of the International Building Code (IBC), which offers a Structural Masonry Special Inspectors Certification Exam that is co-sponsored by TMS.

For additional information on availability of masonry inspection training programs and the Structural Masonry Special Inspectors Certification Exam, contact TMS or ICC.

Building Code Requirements for Masonry Structures and Specification for Masonry Structures and Commentaries, Masonry Standards Joint Committee, American Concrete Institute, American Society of Civil Engineers, The Masonry Society, Longmont, Colorado, 2013.

2012 International Building Code, International Code Council, Inc., Country Club Hills, 2011.